Diagnostic workshop [DM1]

Overview of the DM1 diagnostic workshop

The DM1 diagnostic workshop is a new development by the LOCKER Design Bureau. The workshop is built on the basis of a 20-foot marine container and is intended for performing, in field conditions, diagnostic and repair work on hydraulic and fuel equipment, starters, generators, and other units and assemblies of passenger cars, trucks, and special-purpose vehicles. During the maintenance of vehicle wheels, the workshop can be used either independently or in combination with other service and repair facilities. The workshop can be operated either directly on the ground or mounted on a vehicle (container truck, trailer). The container is secured on the vehicle using standard transportation fasteners. For proper operation of the equipment and convenient access to the workshop units, the container is equipped with side hatches.

| Name of the supplied item: |

| DM1 diagnostic workshop |

| NATO stock number: |

| 4910-61-018-2543 |

Custom-designed electrical switchboard, engineered for high loads and specifically tailored to support the simultaneous operation of all electrical equipment.

A source of electrical power that provides a stable supply at any time and in any location. It serves as a reliable power source in field conditions. Operating power: 13 kW.

Equipped with a 200-liter compressor to ensure maximum efficiency of pneumatic tool operation.

Professional equipment for inspecting, cleaning, and restoring the performance of fuel injectors. It enables pressure testing that simulates real engine operating conditions, as well as ultrasonic cleaning to remove contaminants. Used in auto service centers to improve fuel system efficiency and reduce fuel consumption.

- Injector type: gasoline

- Number of injectors: 6

- Ultrasonic bath power: 60 W

Specialized equipment for testing, adjusting, and diagnosing hydraulic components such as pumps, valves, and hydraulic cylinders. It simulates real operating conditions, allowing assessment of system performance, tightness, and working pressure.

- Working fluid viscosity range: 20–200 cSt

- Recommended oil temperature: 40–55 °C

- Tank volume: 230 L

- Rated pump pressure: 25 MPa

Equipment for testing the performance and efficiency of generators used in cars and special machinery. It allows testing voltage, current, power, and operation under load, simulating real operating conditions. Used in auto service centers and repair workshops for timely fault detection and improving the reliability of vehicle electrical systems.

- Generator voltage: 12, 24 V

- Maximum number of connected batteries: 2 pcs, 12 V each

- Starter testing: up to 6 units

- Measured parameters: stabilization voltage; AC current; DC current; drive speed.

Designed to improve the efficiency and convenience of handling heavy loads during repair work. Maximum lifting capacity – 500 kg.

Equipment that uses hydraulic pressure up to 30 tons for compressing, forming, or pressing materials. It is used for pressing-in, bending, pulling, and other operations.

Equipment for storing, pumping, and metered dispensing of engine and technical oils. Ensures convenience, cleanliness, and consumption control during equipment maintenance.

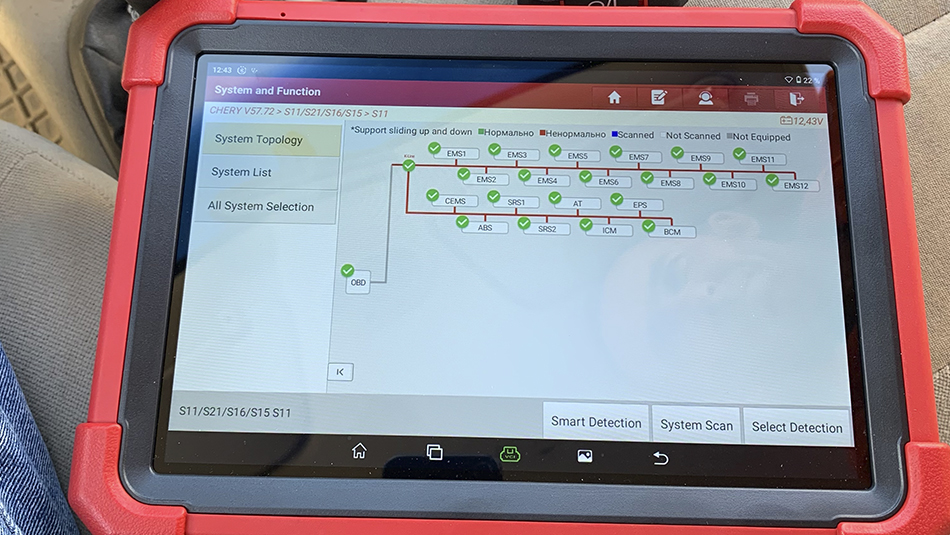

A diagnostic device for reading and analyzing the operation of vehicle electronic systems. It connects via the OBD-II port and allows checking the condition of most systems and modules.

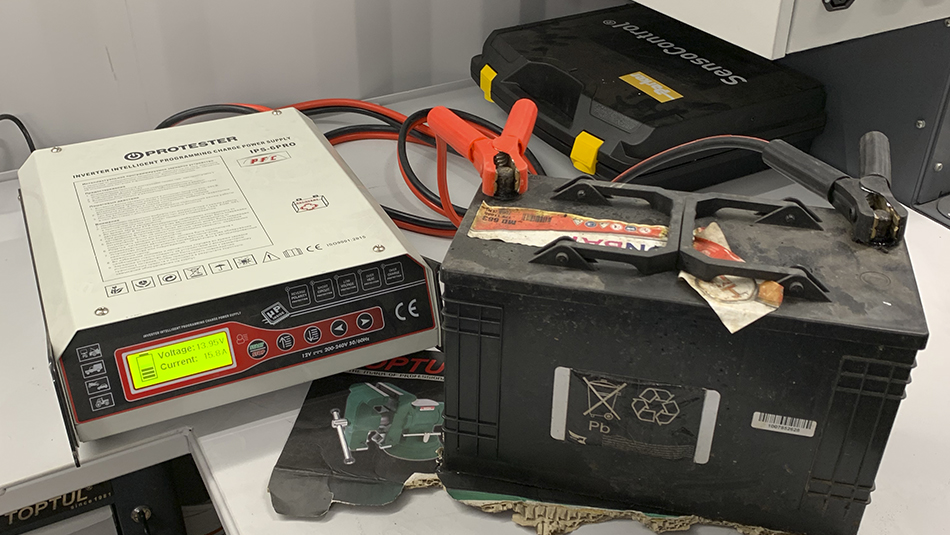

A device for checking the condition of vehicle batteries. It measures voltage, capacity, charge level, and starting current, helping to assess the battery’s performance.

Equipment for charging batteries and starting the engine when the battery is discharged. Suitable for passenger cars, trucks, and special-purpose vehicles.